INVENT’s Floating Mixer-Aerators

JIPL Brings INVENT’s Innovative Wastewater Solutions to New Zealand

INVENT’s groundbreaking Floating HYPERCLASSIC®-Mixing and Aeration System is gaining significant traction in Sweden’s industrial wastewater treatment sector, especially in lagoon-based plants within the pulp and paper industry. These facilities are built to tackle the unique challenges of wastewater treatment and demand highly efficient aeration solutions.

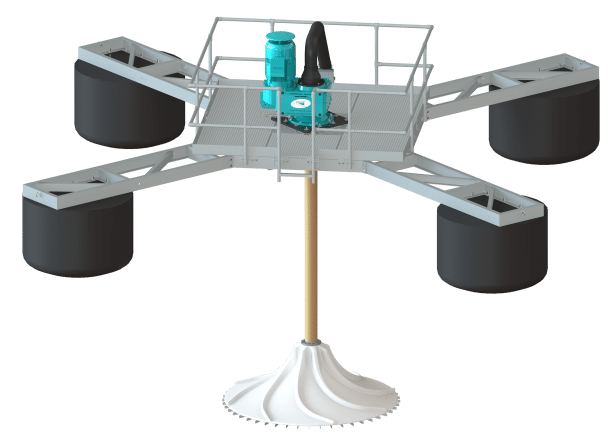

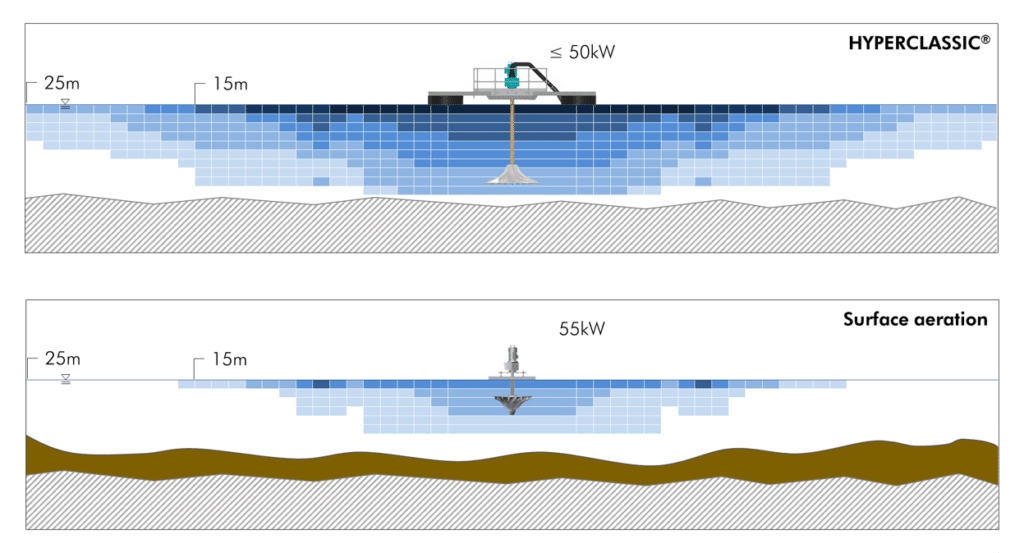

Traditional technologies—such as surface, membrane, and submerged aerators—often encounter issues due to poor circulation, underutilized volumes, and high maintenance demands. The HYPERCLASSIC®-Mixing and Aeration System overcomes these issues by being mounted on a floating platform, enabling aeration near the bottom and achieving optimal mixing through high turbulence.

Real-World Successes in Sweden

The system’s adoption in Sweden has led to remarkable improvements in performance and efficiency:

- Enhanced Aeration Performance: One plant replaced its membrane aeration system with the HYPERCLASSIC® System, increasing aeration performance by 30% without the need for additional blowers. This boost reduced maintenance costs while delivering more efficient wastewater treatment.

- Fewer Aerators, Higher Efficiency: Another Swedish facility replaced three surface aerators with a single HYPERCLASSIC® System, maintaining consistent dissolved oxygen levels and cutting maintenance down to just an oil change every two years.

- Handling Increased Production Volumes: In Northern Sweden, a facility installed six mixing and aeration systems, which allowed for the decommissioning of old surface and submersible aerators. This upgrade helped the plant meet higher production demands without compromising on performance.

These case studies illustrate the system’s versatility and cost-saving benefits, whether through reducing the number of aerators or cutting down on long-term maintenance requirements.

Innovative Design for Simple Installation

The HYPERCLASSIC® System is mounted on a floating steel platform, optionally equipped with a maintenance deck for easy access during routine tasks like oil changes. Connected to compressed air, the system operates without the need for high maintenance and fixed equipment inside the tank. Its smart design allows for easy installation on land, followed by lifting the unit into the lagoon for final setup. Once in place and connected to the process air, the system is ready for operation.

Figures and schematics (like Figure 1) demonstrate the significant improvements in aeration volume at a 5-meter depth compared to traditional systems.

A Proven Solution with Global Impact

Launched in 2019, the Floating HYPERCLASSIC®-Mixing and Aeration System has consistently delivered outstanding results, not only in Sweden but also in other regions. INVENT’s engineering team in Erlangen customizes each solution to meet specific industrial needs, leveraging local materials and services for production.

With its cutting-edge technology, JIPL is proud to bring INVENT’s wastewater solutions to New Zealand, setting new benchmarks for sustainability and performance in wastewater treatment.