JIPL is revolutionising wastewater management in New Zealand’s food and dairy sectors through our partnership with the KWI Group — global leaders in Dissolved Air Flotation (DAF) technology. Together, we deliver innovative, compact, and sustainable systems that help processors meet strict regulatory standards, improve operational efficiency, and minimise environmental impact.

As environmental regulations grow tighter and consumers demand greater accountability, food and dairy producers must find smarter ways to manage wastewater. DAF technology has proved essential, offering a reliable, high-performance solution for treating the complex, high-strength effluent generated in modern processing plants.

Why DAF Technology Matters

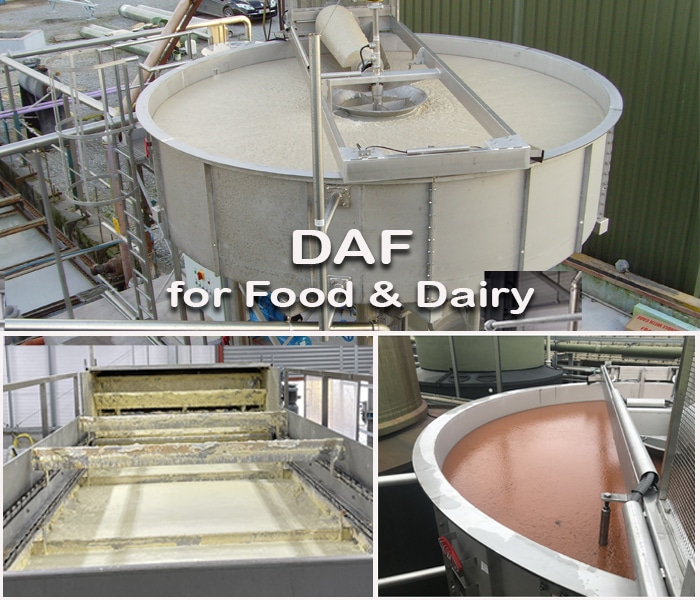

DAF systems clarify wastewater by dissolving air under pressure and then releasing it to form microbubbles. These attach to suspended solids, fats, oils, and greases (FOG), lifting them to the surface where they can be removed. This makes DAF particularly effective for food and dairy effluents, which typically contain high levels of organic matter, fats, and proteins.

Specialised KWI Solutions for Food & Dairy Wastewater

KWI offers one of the broadest and most versatile ranges of DAF systems in the world, with over 7,000 units installed across 90 countries. Their portfolio includes standard models such as Ecocell, Minicell, Megacell, and Supracell, alongside fully customised options designed to handle everything from primary wastewater treatment to product recovery and water reuse.

Key Applications:

- Effluent Treatment: Efficient removal of solids, fats, and organics from food and dairy production.

- Product Recovery: Capture of valuable fats, proteins, and by-products that would otherwise be lost.

- Water Recycling: Enables water reuse for washdown or process water, reducing consumption and costs.

Applications in the Food & Dairy Sector

- Effluent Treatment: Rapid and effective removal of suspended solids, FOG, and organic loads from food and dairy processing.

- Product Recovery: Capture of valuable by-products that would otherwise be lost in the effluent stream.

- Water Recycling: Treat and reuse water to reduce operational water consumption and meet sustainability goals.

Advantages of KWI DAF Technology

- Compact Footprint – Ideal for space-constrained facilities

- Low Energy & Chemical Use – Efficient, sustainable operation

- High Sludge Concentration – Up to 5% solids for reduced disposal volume

- Custom Solutions – Configured for the specific wastewater profile of each site

- Environmental Compliance – Supports local discharge and sustainability targets

Case Studies: Global Proof of Performance

Dairy: Glanbia Cheeses, Anglesey (Mozzarella Production)

KWI’s Minicell system removed phosphates and reduced COD. Clarified water was reused, and valuable sludge was efficiently handled via a decant system.

Food: Pennine Foods, UK

A KWI MNC 12 DAF unit achieved over 90% reduction in suspended solids, 80%+ FOG removal, and 50% COD reduction at this major frozen food plant.

Dairy: Müller Market (Yogurt Production)

The MCH30 DAF unit treats both biological sludge and primary effluent—without chemicals—reducing environmental impact.

Dairy: Arla Creamery, UK

A Megacell MCH clarifier was installed for full effluent treatment, with fat recovery and minimal chemical input. A second DAF manages downstream processing.

Compact, Turnkey Solutions: The Supracell Advantage

Space is often a limitation in existing processing plants. KWI’s Supracell model, now available as a skid-mounted unit, arrives pre-wired, tested, and ready for rapid deployment. Originally designed for the pulp and paper industry, Supracell has proven equally effective for dairy applications, especially where space, ease of installation, and fast commissioning are critical.

Many legacy DAF plants in New Zealand’s dairy sector are large and inefficient. KWI’s systems offer a modern, compact alternative that delivers superior performance while reducing operational and maintenance costs. Whether you’re producing cheese, butter, ice cream, yoghurt, or convenience foods, there’s a KWI DAF system optimised for your needs.

Partner with JIPL

At JIPL, we provide end-to-end support for the supply, installation, and maintenance of KWI DAF systems across Aotearoa. From initial consultation to full integration, our experienced team works with food and dairy processors to deliver smart, sustainable solutions that meet operational, environmental, and economic goals.